You are interested in? Do you have any questions?

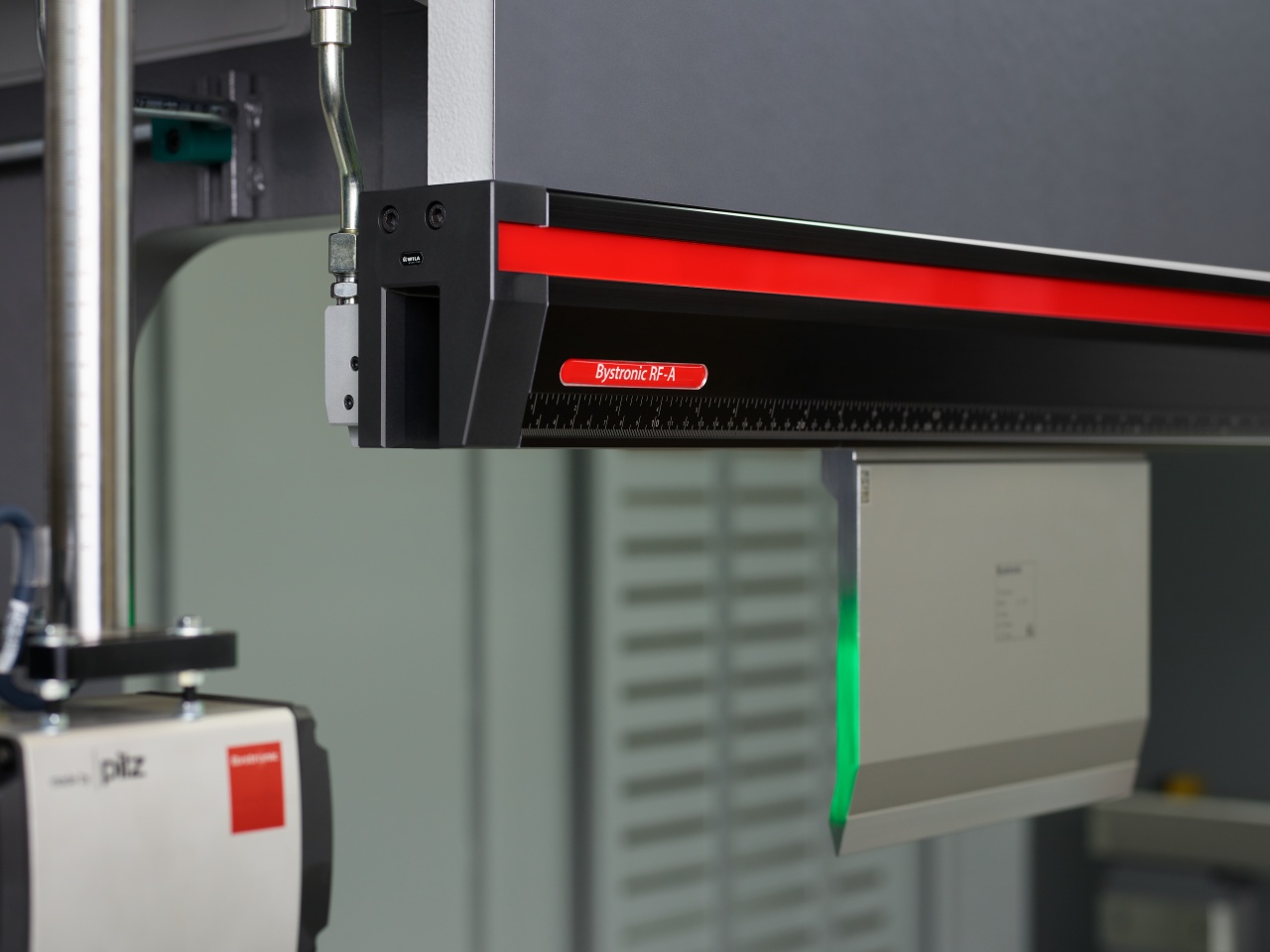

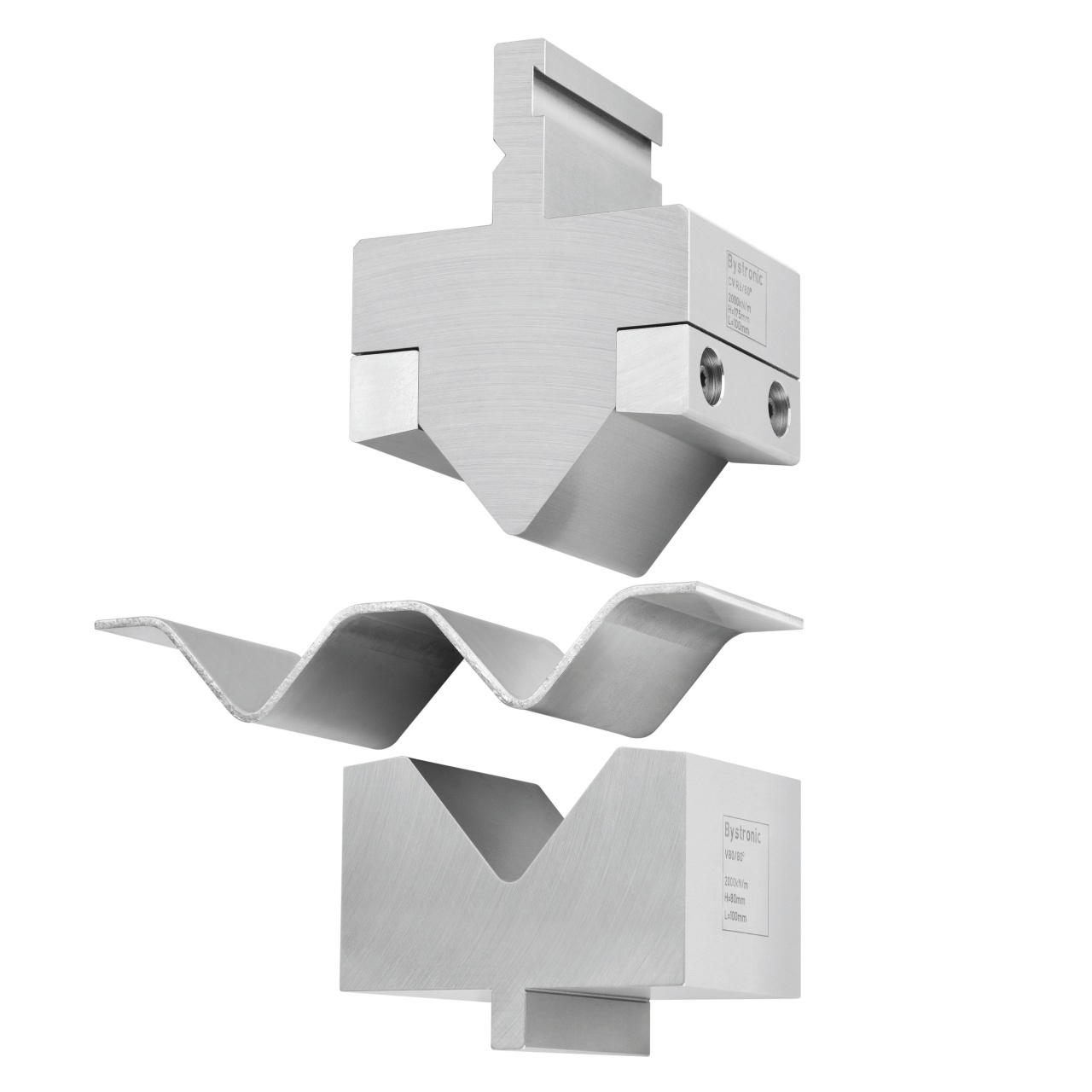

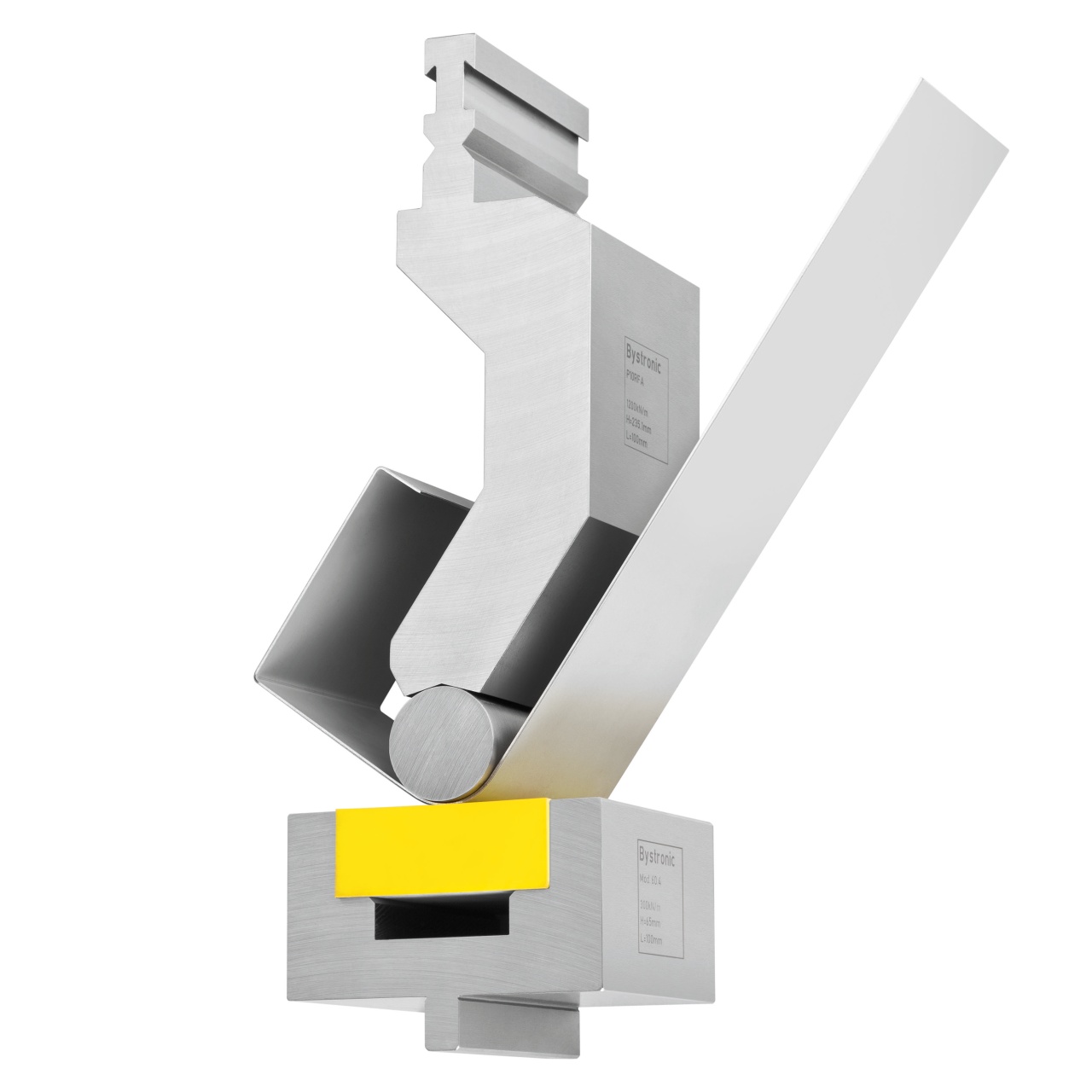

Metal sheet bending

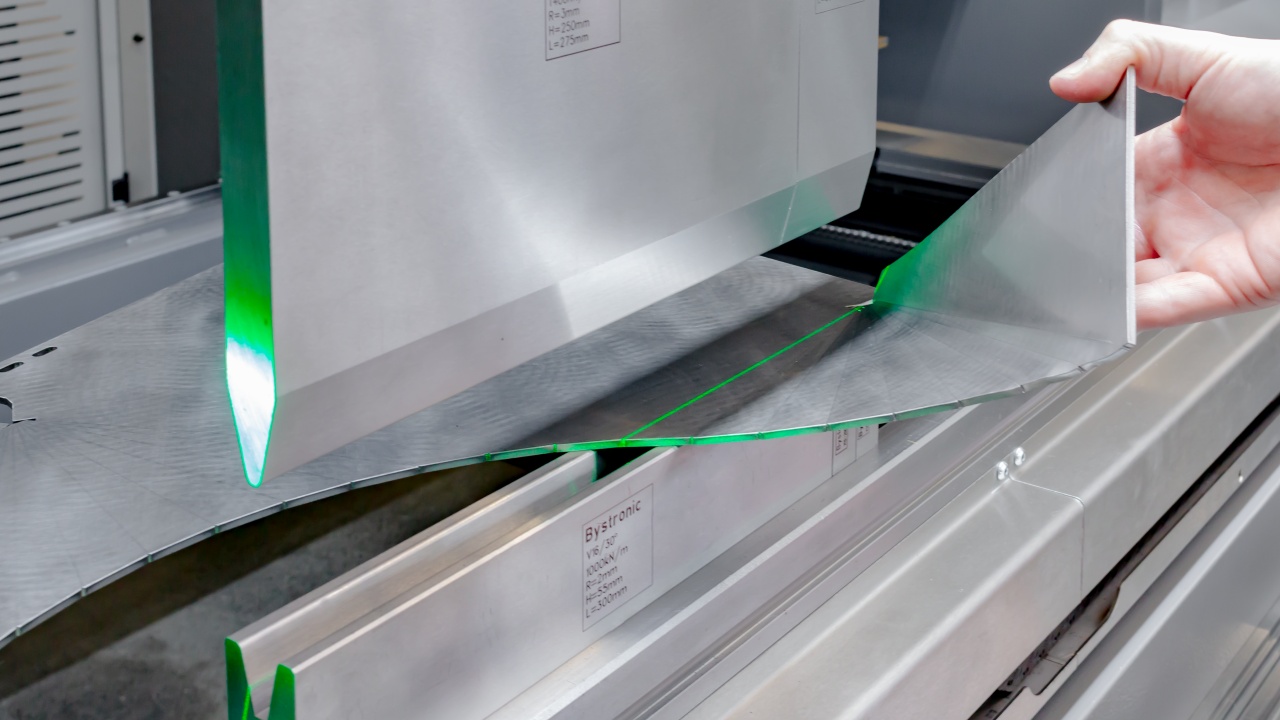

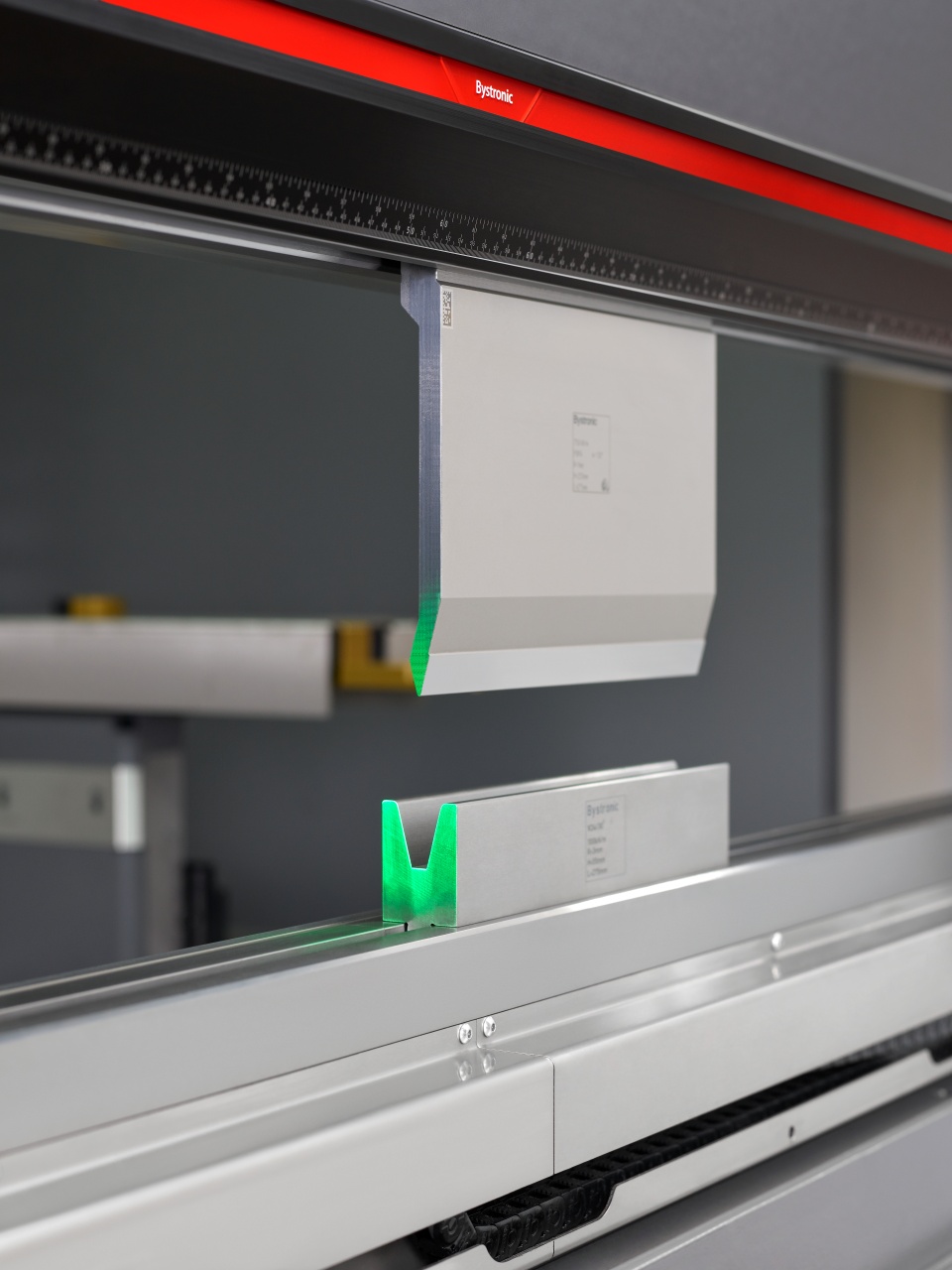

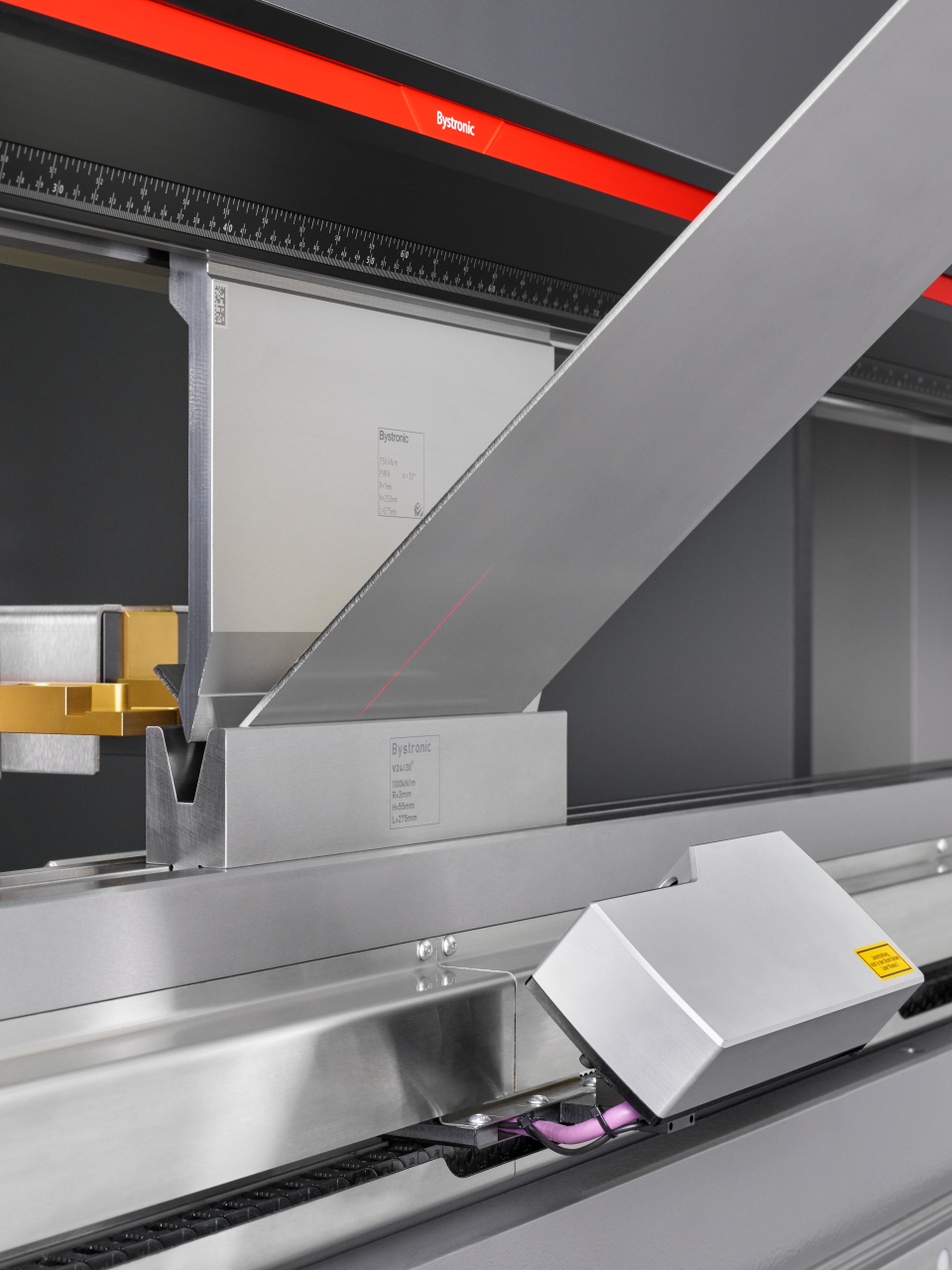

Sheet metal bending on press brakes is a technology representing the next step in steel processing, after laser cutting. We have press brakes with pressures of up to 250 tons. We are capable of performing bends of up to 4m in length. Depending on the length of the bending line, the maximum thickness of the bent sheets is 12 mm. The process of bending on a press brake combined with laser cutting gives us the opportunity to serve our customers more comprehensively. Laser cut and bent parts stand out with their high precision and excellent repeatability of shapes. The applied technology of dynamic compensation of the deflection arrow enables high precision and repeatability of shapes for both short series and large orders. By commissioning our company to bend metal sheets, you can be sure of the final quality of the product. Our experienced engineers know how to use the full potential of our modern machine park. INTECHSTAL employees use advanced programming methods to ensure that the CNC steel bending process brings the desired results.

Press brake bending

We perform bending on press brakes with a maximum clearance of 840 mm and a stroke of 430 mm. With the experience we have gained over the years, we are able to handle even the most demanding projects. So far, we have made elements for sectors such as the machinery, construction, petrochemical and agricultural industry. Therefore, if you are looking for a company to provide you with sheet metal bending services, look no further than us. Professional approach to the customer and fast order processing is our motto. This is made possible by our modern machinery and qualified workforce. Do not hesitate then and get in touch with us. You can do this by phone or via the form available on our website. We will be more than glad to answer any questions on order processing or the very process of cutting and bending sheet metal. We are looking forward to successful and rewarding cooperation with you.

WHY CHOOSE US?

Modern machine park

Wide technological possibilities of cutting and bending

Experienced engineers

Advanced software

Fast completion times

OUR PROJECTS

Our service centre provides services for many industries. We stand out with our great attention to detail and speed of delivery. We deliver the finished product with our own vehicles.

- Machinery

- Construction

- Steel Structures

- Advertising

- Furniture

- Petrochemical

- Agricultural

Opinie

Opinie

Nasi Klienci

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06