You are interested in? Do you have any questions?

Laser cutting of sheet metal

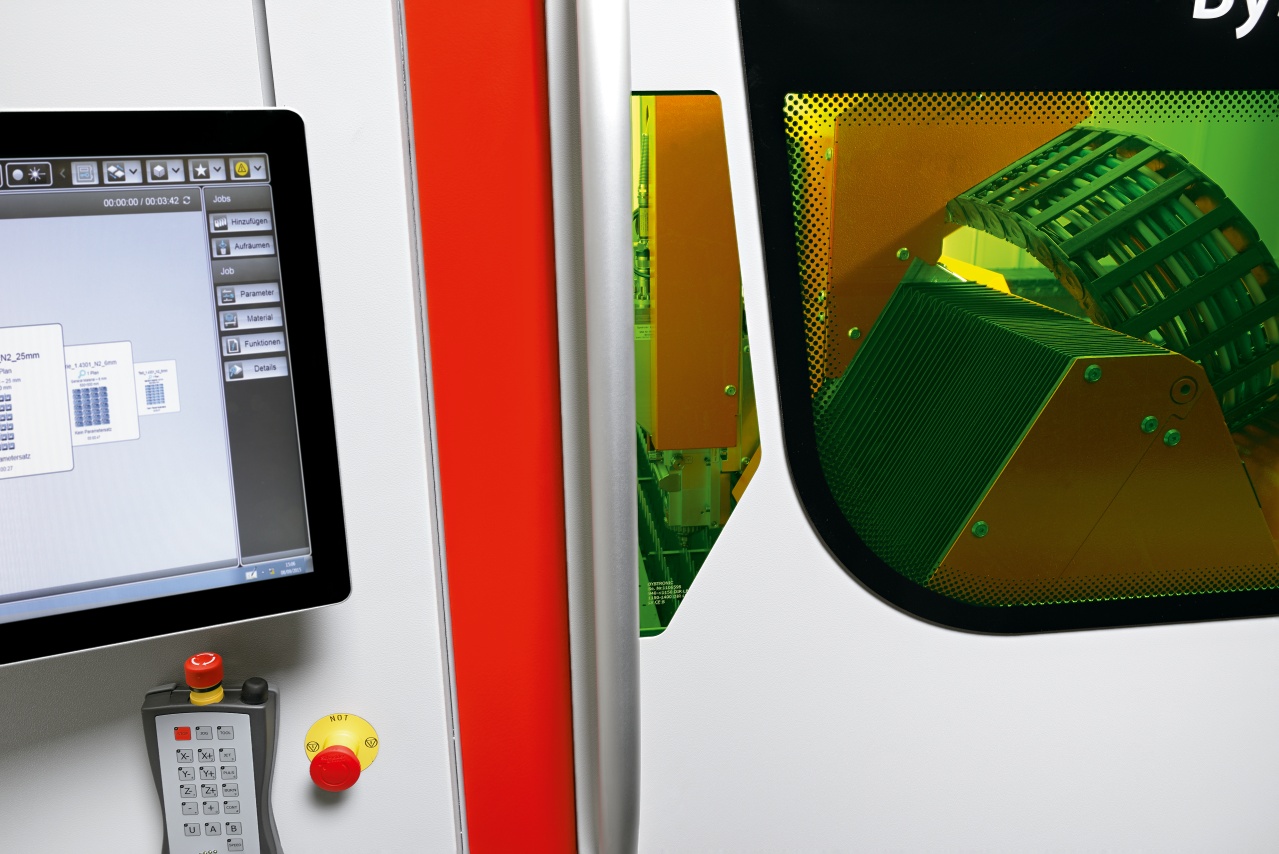

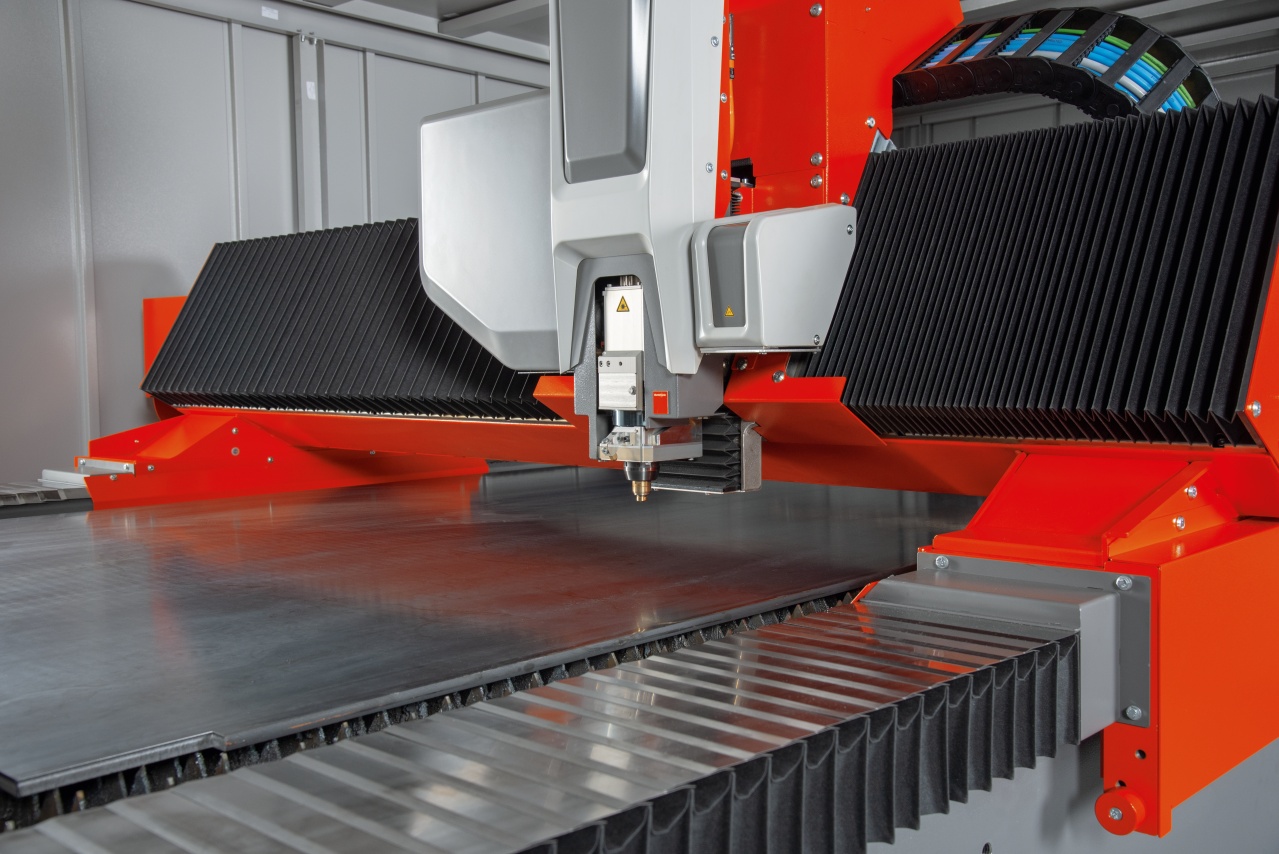

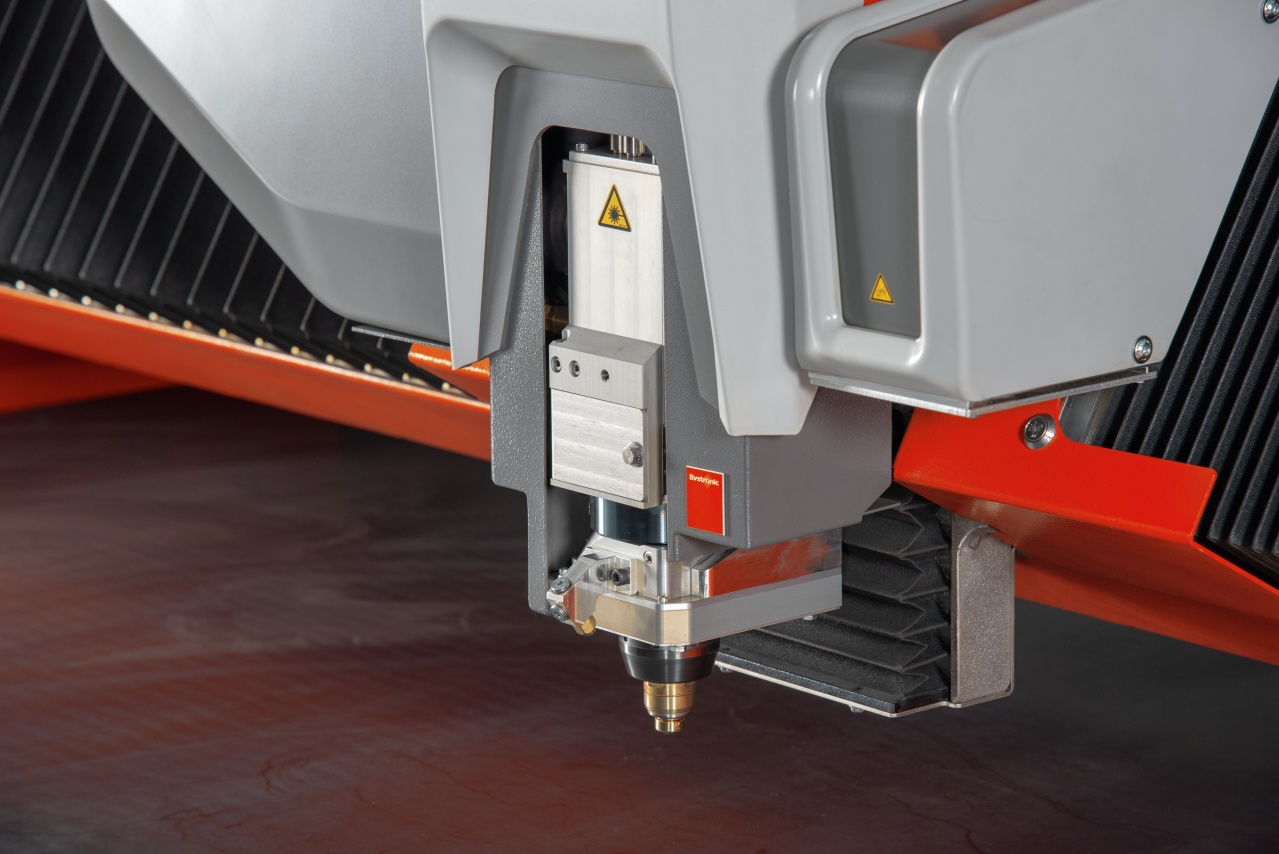

Laser cutting in metal is a processing method which allows for precise cutting of metal sheets. We cut steel using the latest FIBER laser technology.

This technology enables high accuracy and edge quality at a relatively high cutting speed. The FIBER laser is a highly energy-efficient tool. This improves our competitiveness in the full range of thicknesses of structural, stainless and aluminum sheets. A broad range of materials can be processed using laser cutting technology. Virtually all types of sheets can be processed using this technology.

We offer laser cutting of structural steel, stainless steel, aluminium, copper, brass and other sheet metal grades. At the same time, we guarantee high accuracy and edge quality at a high cutting speed for sheets from 0.8 mm to 30 mm thick. The maximum dimensions of sheet metal that we are able to laser cut is 2000 × 4000 mm.

Laser cutting of sheet metal – price

A dynamic development in the laser cutting technology has been noticeable in the recent years. Increasing the power of the resonators generating the laser beam is one of the development directions. Currently we are able to offer laser cutting with one of the most efficient and modern machines. We offer our clients sheet metal laser cutting with the following range of cutting thickness:

- Stainless steel: up to 30 mm

- Structural steel: up to 30 mm

- Aluminium: up to 30 mm

- Brass: up to 15 mm

- Copper: up to 12 mm

The high power of the laser beam enables quick and precise laser cutting. Our high productivity ensures that the customer enjoys a competitive price and fast completion times for production orders.

We understand our clients’ expectations. We provide services to production plants which are continuously improving their own production processes. Automation, robotisation and development of CNC technology in sheet metal processing is becoming an everyday reality. Modern technologies are increasingly replacing traditional production methods.

Modern, high-performance laser cutting machines are quite a significant expense. It is essential to use advanced software and employ engineers and operators to operate the machines. In our company, we constantly train our staff so as to make the most of our machines and advanced computer solutions.

Why choose us?

Modern machine park

Wide technological possibilities of cutting and bending

Experienced engineers

Advanced software

Fast completion times

Our projects

Our service centre provides services for many industries. We stand out with our great attention to detail and speed of delivery. We deliver the finished product with our own vehicles.

- Machinery

- Construction

- Steel Structures

- Advertising

- Furniture

- Petrochemical

- Agricultural

Opinie

Opinie

Nasi Klienci

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06